FURNACES FOR

fluidized

bed combustion

technology

By utilizing the fluidized bed combustion technology in a combustion process

it is possible to incinerate matter in all three states of aggregation, with or without the presence of additional fuel sources. One of the most discussed topics is related to a combustion process which would be efficient, energy-wise, and an ecologically justifiable usage of low grade fuel, crude oil residues, and other ballast materials.

The advantages of combustion processes with fluidized bed combustion

Substances of low thermal power and high levels of humidity (up to 90%), contained within a fluidized bed of sand of great thermal capacity, are inherently very quick to release moisture and are then usable in combustion processes just like any other quality source of fuel. In case that a substance cannot reach the desired combustion temperatures above 800°C through its own thermal potential energy, it is necessary to insert any other source of conventional fuel in the fluidized bed, to act as an auxiliary source of thermal energy. A similar statement could be made regarding fuel sources which are by default accompanied by a huge percentage of ash (up to 70%). In this case, the combustion processes take place at the temperatures ranging from 750°C through 900°C. Due to such high temperatures, ash gets neither melted nor does it adhere to and contaminate the heating surface, and the chances of the NOx formations appearing are reduced to a minimum. By inserting a dosage of limestone into the fluidized bed, we enable a direct desulfurization process, which will separate sulfur compounds from the fumes, even up to 90% within the combustion chamber itself. Solid fuel substances, whose granules range in size from 0 to 35mm, are successfully burned in a fluidized bed, which means that there is no need for any special treatment processes of the fuel substances. Additionally, contaminated liquids, emulsions, sludge, and substances in the state of powder can also be combusted. These furnaces and boilers are constructed in such a manner that, apart from the ventilator, all other parts of the equipment are fixed and immobilized in their designated positions, and no fire-retardants can be inserted. The ability of our combustion chambers to use even cheap, low-quality fuel provides for low operating costs.

What do we offer?

- Analyzing the possibility of utilizing even more difficult-to-use fuel sources and ballast substances

- Defining the design parameters of desired plants and facilities

- Development of techno-economic assessments, according to the standards set by the EU, which includes

- Thermal performance assessment

- Calculating the necessary funds for every piece of the necessary equipment, as well as the cost of the entire facility

- A discounted cash flow economic analysis

- When necessary, assisting with the main project and helping with the organization of the production process

- Conducting performance tests and long-term observation of a facility, after the construction process has been completed

What kinds of substances have we used in combustion processes?

- Aflatoxin-contaminated corn

- Fruit stones

- Marc

- Corn cob

- Contaminated biomass

- Oil sludge and oilseed processing residues

- Low-quality coal (high percentage of humidity and ash present)

- Many other sources of fuel, utilizing their energy potential, always in accordance with the environmental protection regulations

An experimental, industrial-scale plant

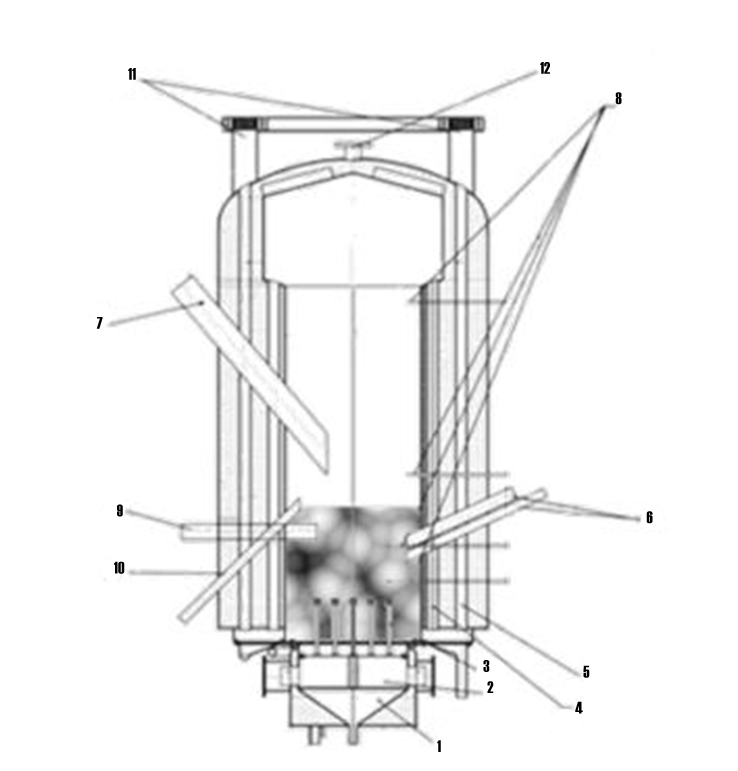

A schematic diagram of an industrial furnace with a fluidized bed, with a nominal capacity of 500kW (please see the picture)

- Water-cooled collector for the removal of ash and other inert matter

- Air handling unit

- Major air-handler components

- Smokestacks and steeples (Section I)

- Smokestacks and steeples (Section II)

- Angled grommets for pneumatic actuators for administering fuel substances into a fluidized bed

- Angled grommets for administering fuel substances onto the fluidized bed

- Ceramic pipes with thermocouples, accompanied by temperature data acquisition systems

- Horizontal grommet for introducing solid fuel into the fluidized bed

- Overflow pipe for draining ash from the fluidized bed

- Flue for conveying exhaust gasses

- Water outlet from the boiler